When you first start working with a vinyl cutter, it’s easy to assume that a blade is just a blade. They are small, sharp, and seem simple enough. However, the world of vinyl cutter blades is more nuanced than it appears. The angle of the blade, most commonly 45 degrees or 60 degrees, plays a critical role in determining the quality and success of your cuts. Choosing the wrong blade for your material can lead to frustration, wasted vinyl, and poor results.

Understanding the difference between these two primary blade types is essential for anyone looking to master their cutting machine. The angle doesn't just change the blade's shape; it changes how it interacts with the material you're cutting. One is a versatile workhorse for everyday projects, while the other is a specialist designed for heavy-duty tasks. Let's break down the key differences to help you choose the perfect blade for every project.

Understanding Blade Angle

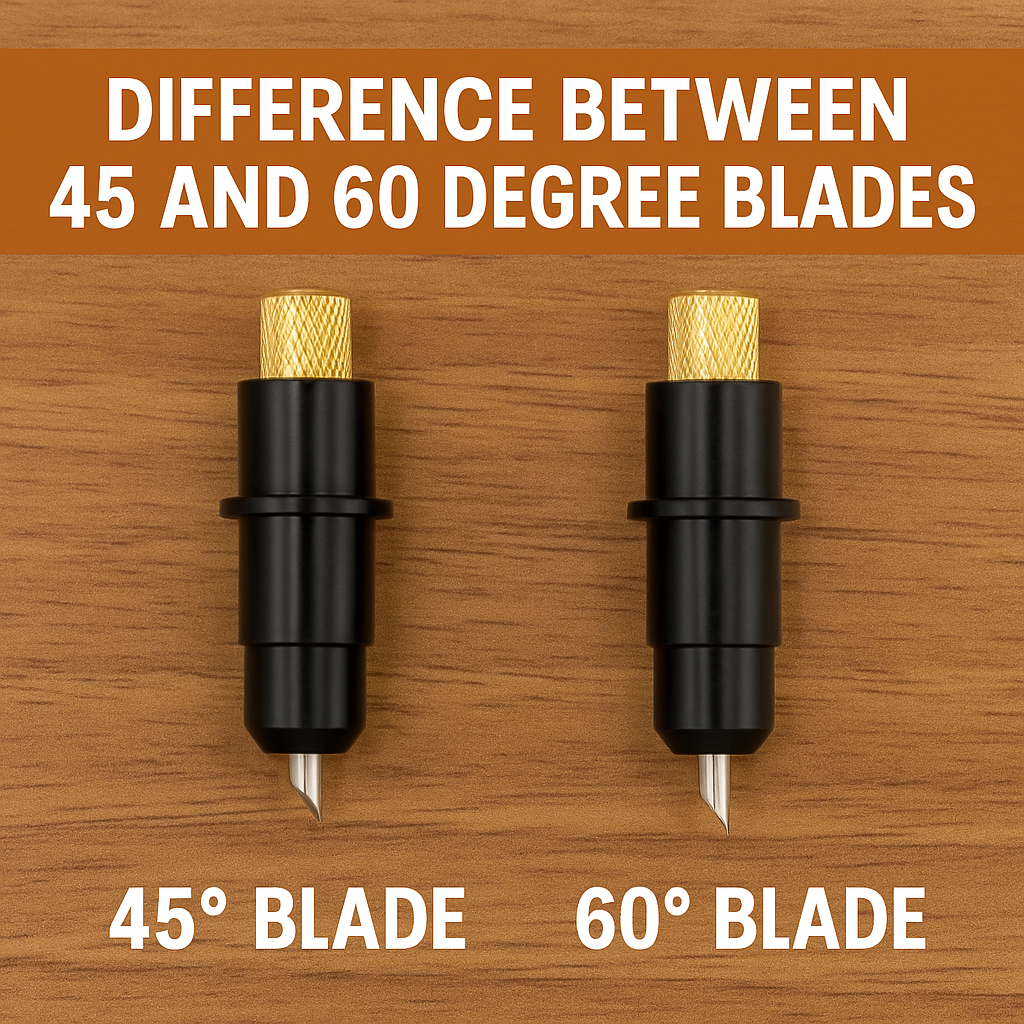

The "degree" of a vinyl cutter blade refers to the angle of the cutting tip. A 45-degree blade has a sharper, more pointed tip, while a 60-degree blade has a more obtuse, broader tip. This angle directly impacts how much of the blade's cutting edge is in contact with the material at any given time.

Imagine trying to cut through a thick piece of cardboard. A very narrow, pointy knife (like a 45-degree blade) might struggle or even break because it lacks the structural strength to push through the tough material. A wider, more robust blade (like a 60-degree blade) can handle the resistance more effectively. This same principle applies to vinyl cutter blades.

The blade's angle, combined with its "offset"—a setting on your machine that accounts for the distance between the blade tip and the center of the blade holder—determines the cutter's ability to navigate curves and corners cleanly.

The 45-Degree Blade: Your Everyday Standard

The 45-degree blade is the most common and versatile option available. In fact, most vinyl cutters come with a 45-degree blade pre-installed. It’s the go-to choice for the majority of cutting jobs, and for good reason.

What It’s Best For

The sharp, narrow point of a 45-degree blade allows it to pivot quickly and cut fine details with exceptional precision. This makes it ideal for standard and thinner materials.

Use a 45-degree blade for:

- Standard adhesive vinyl (like Oracal 651 or StarCraft HD)

- Standard heat transfer vinyl (HTV) (like Siser EasyWeed or StarCraft SoftFlex)

- Paper and light cardstock

- Sticker paper and inkjet printable vinyl

- Materials up to approximately 0.25mm thick

Advantages of the 45-Degree Blade

- Precision on Fine Details: Because less of the blade surface is in contact with the material, it can make sharper turns without tearing or snagging. This is crucial for cutting intricate fonts, complex patterns, and small designs.

- Versatility: It handles the widest range of common crafting materials, making it a reliable workhorse for everyday projects.

- Longevity: Since it’s used on less demanding materials, a 45-degree blade often has a longer lifespan compared to a 60-degree blade that is constantly put to work on tough substrates.

When to Avoid It

A 45-degree blade will struggle with thick or dense materials. The fine tip is not robust enough to cut through them cleanly. Using it on materials like glitter HTV or sandblast mask can cause incomplete cuts, jagged edges, or even break the blade tip.

The 60-Degree Blade: The Heavy-Duty Specialist

When your projects demand more power, the 60-degree blade is the tool for the job. Its wider angle gives it the strength and stability needed to slice through thicker, denser, and more challenging materials.

What It’s Best For

The 60-degree blade has more of its cutting edge exposed, allowing it to carve through tough substrates that would damage a standard blade. Think of it as the deep-cut or heavy-duty option in your toolkit.

Use a 60-degree blade for:

- Thick, dense materials like glitter HTV and flock HTV

- Reflective and holographic vinyl

- Sandblast resist mask and stencil vinyl

- Thick cardstock and chipboard

- Fabric, canvas, and twill

- Magnetic sheeting

Advantages of the 60-Degree Blade

- Cutting Power: It cleanly cuts through materials that a 45-degree blade can't handle. The robust tip resists chipping and breaking under pressure.

- Clean Cuts on Thick Materials: It provides smooth, complete cuts on thick substrates, which is essential for easy weeding and a professional finish.

When to Avoid It

While powerful, the 60-degree blade is not ideal for very small, intricate designs. Because more of the blade surface drags through the material, it can have trouble with sharp corners and tiny details, sometimes causing them to lift or get mangled. The wider cutting path can make it less nimble than its 45-degree counterpart on standard vinyl.

How to Choose the Right Blade for Your Project

Choosing between a 45-degree and 60-degree blade is a simple matter of evaluating your material.

Here's a quick decision-making guide:

- Assess Your Material: Is it a standard vinyl like Siser EasyWeed or Oracal 651? Is it thin like paper? If yes, start with a 45-degree blade.

- Consider Thickness and Density: Is your material thick, textured, or tough? Examples include glitter HTV, reflective vinyl, or sandblast mask. If yes, use a 60-degree blade.

- Analyze Your Design: Does your design have extremely fine, delicate details? A 45-degree blade will almost always perform better here, provided the material is suitable. For blocky text or larger shapes on thick material, the 60-degree blade is perfect.

- Perform a Test Cut: This is the most crucial step! Before committing to cutting your full design, always perform a small test cut. This allows you to check if the blade, force, and speed settings are correct for your material, saving you from wasting an entire sheet of vinyl.

Don't Forget Your Blade Offset!

When you switch between blade angles, you may also need to adjust your blade offset setting. The offset value compensates for the distance from the point of the blade to its center axis, ensuring clean corners. Check your cutter's manual for recommended offset settings for different blades. A 60-degree blade generally requires a larger offset value than a 45-degree blade.

Build Your Blade Toolkit

Having both 45-degree and 60-degree blades in your craft arsenal is not a luxury; it’s a necessity for any serious crafter or business owner. Using the right blade for the job ensures you get the best possible results, saves you time and frustration during weeding, and extends the life of both your blades and your cutting machine. By understanding the specific strengths of each blade, you empower yourself to tackle any project with confidence, from delicate lettering on standard vinyl to bold designs on heavy-duty materials.

Ready to equip your cutter for any challenge? Having the right tools on hand makes all the difference.