Have you ever wondered how people create those incredibly vibrant, full-color designs on coffee mugs, phone cases, or polyester t-shirts that seem to be infused directly into the material? The colors are brilliant, the edges are sharp, and you can’t feel the design at all. This isn't paint or a sticker; it's the result of a fascinating scientific process called dye-sublimation.

Sublimation printing allows for the creation of permanent, photo-quality images that won't crack, peel, or fade over time. It has become a cornerstone of the personalized products industry, empowering both hobbyists and businesses to turn blank items into custom works of art. Understanding how this process works is the first step toward mastering it. Let's break down the science, the supplies, and the steps to demystify sublimation.

The Science Behind Sublimation

At its core, sublimation is a chemical process where a substance transitions directly from a solid to a gas state, completely skipping the liquid phase. Think of dry ice: it's solid carbon dioxide that turns into a gas "fog" without ever melting into a puddle. Dye-sublimation printing uses this same principle to transfer images onto a surface.

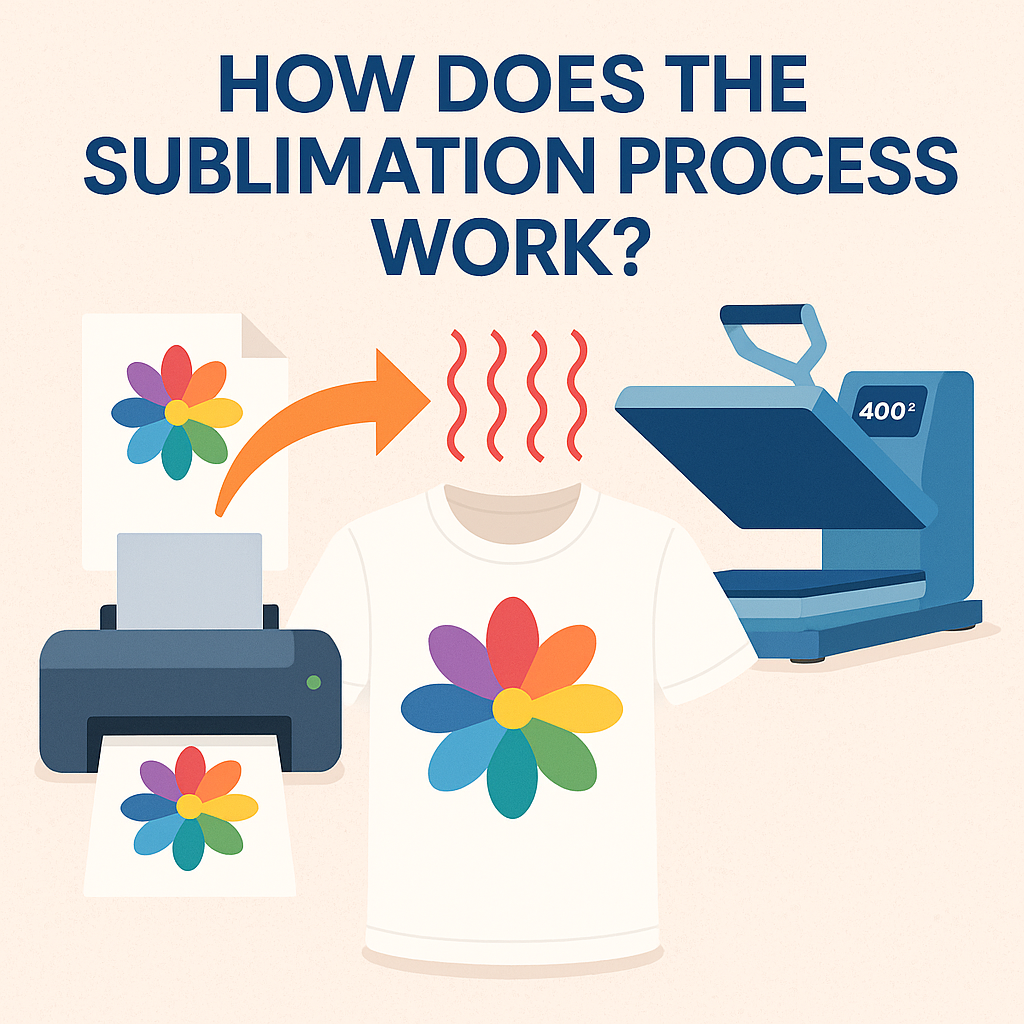

Here’s how it works in the context of printing:

Solid Ink: Designs are printed onto special transfer paper using solid sublimation inks. At room temperature, this ink is essentially a solid pigment suspended in a liquid carrier.

Heat and Pressure: The printed transfer paper is placed onto a polyester-coated item or a polyester fabric. It is then subjected to high heat (typically 380-400°F or 195-205°C) and firm pressure from a heat press.

Gas Transition: The intense heat causes the solid sublimation inks to turn into a gas. Simultaneously, the heat opens up the pores of the polyester material.

Permanent Bond: The gaseous ink permeates the open pores of the substrate. As soon as the heat is removed, the pores of the polyester close, permanently trapping the ink within the material. The ink then turns back into a solid, bonded with the fibers of the substrate.

The result is a design that is not sitting on top of the material, like with screen printing or heat transfer vinyl (HTV), but is embedded inside it. This is why you can't feel a sublimation transfer and why it is so incredibly durable.

Essential Supplies for Sublimation Printing

To get started with sublimation, you need a specific set of tools and materials. Unlike other crafting methods, there isn't much room for substitution here, as the process relies on the unique properties of each component.

A Sublimation Printer

You cannot use a standard inkjet or laser printer. A sublimation printer is an inkjet printer that is either purpose-built for sublimation (like a Sawgrass) or has been converted for sublimation use (like certain Epson models) and is filled exclusively with sublimation ink. Using regular printer ink will not work.

Sublimation Ink

This special ink is the key to the entire process. It's formulated to transition from a solid to a gas under heat and pressure. The colors on the printed paper will look dull and faded—this is normal! The true, vibrant colors will only appear after the heat-pressing stage.

Sublimation Transfer Paper

This is not just regular paper. Sublimation paper has a special coating that holds the ink but is designed to release it as a gas when heated. Using the wrong paper will result in a blurry or faded transfer.

A Heat Press

A standard home iron will not work for sublimation. A heat press is required to provide the consistent, high temperature and even pressure needed to trigger the chemical reaction. The type of press you need (clamshell, swing-away, or mug press) depends on the items you want to create.

Sublimation Blanks

Sublimation works by bonding with polyester. Therefore, you can only sublimate on materials that are either 100% polyester or have a special polyester coating. These are known as "sublimation blanks."

- Apparel: Must be at least 50-65% polyester for a vintage/faded look, and 100% polyester for the most vibrant, full-color results. Sublimation ink does not bond with cotton.

- Hard Goods: Items like mugs, tumblers, phone cases, keychains, and coasters must have a polymer coating specifically designed for sublimation. You cannot use any old mug from the store.

Other Accessories

You’ll also need heat-resistant tape to hold your transfer paper in place, butcher paper or a Teflon sheet to protect your heat press from ink blowouts, and design software to create your images.

The Step-by-Step Sublimation Process

Once you have your supplies, the process is straightforward. Let’s walk through the steps of sublimating a t-shirt.

- Create Your Design: Use design software like Adobe Photoshop, Affinity Designer, or Sawgrass CreativeStudio to create or edit your image. Remember to mirror your design before printing, especially if it includes text.

- Print the Transfer: Print your mirrored design onto the sublimation transfer paper using your sublimation printer. The colors will look muted.

- Prepare the Garment: Set your heat press to the recommended temperature and time for your specific blank. Place your polyester shirt on the press and pre-press it for 5-10 seconds. This removes any moisture and wrinkles, ensuring a clean surface.

- Position the Transfer: Place the printed transfer paper face down onto the shirt. Use a few pieces of heat-resistant tape to secure it in place so it doesn't shift during pressing, which can cause "ghosting" or blurry edges.

- Protect Your Press: Place a sheet of butcher paper over the transfer paper and garment. This prevents any ink from bleeding through and staining your heat press's top platen. It’s also wise to place butcher paper inside the shirt to prevent bleed-through to the back.

- Press the Design: Close the heat press and apply firm pressure for the recommended time (usually 45-60 seconds for apparel).

- The Big Reveal: When the timer beeps, open the press and carefully remove the transfer paper while it's still hot. You will see your design has magically transferred to the shirt in full, vibrant color.

Why Choose Sublimation?

Sublimation offers several distinct advantages that make it a popular choice for creating personalized products.

- Unmatched Durability: Since the ink becomes part of the material, the design is permanent. It will not crack, peel, fade, or wash out.

- Vibrant, Full-Color Designs: Sublimation allows for printing unlimited colors, gradients, and photographic images with stunning detail and clarity.

- No Feel on Fabric: On apparel, the sublimated design has zero texture, leaving the fabric soft and breathable.

- Professional Finish: The high-quality, permanent results are perfect for creating retail-quality products.

Tips for Beginners

Sublimation has a learning curve, but these tips can help you avoid common mistakes:

- Always Do a Test Press: If you have extra material or a similar item, do a small test before committing to your final product.

- Check Your Settings: Different blanks require different time, temperature, and pressure settings. Always consult the manufacturer's recommendations.

- Beware of Moisture: Any moisture in the paper or substrate can create splotches or color shifts. Always pre-press your garments.

- Use High-Quality Images: The final print will only be as good as the original image file. Use high-resolution images (300 DPI is recommended) for the best results.

Is Sublimation Right for You?

Dye-sublimation is a powerful method for anyone serious about creating high-quality, long-lasting custom products. While the initial investment in equipment is higher than some other crafting hobbies, the professional results and wide range of creative possibilities are unparalleled. From personalized gifts to branded merchandise, sublimation opens up a world of potential.

Ready to dive into the vibrant world of sublimation? Explore our range of supplies to find the printers, inks, and blanks you need to start your journey.