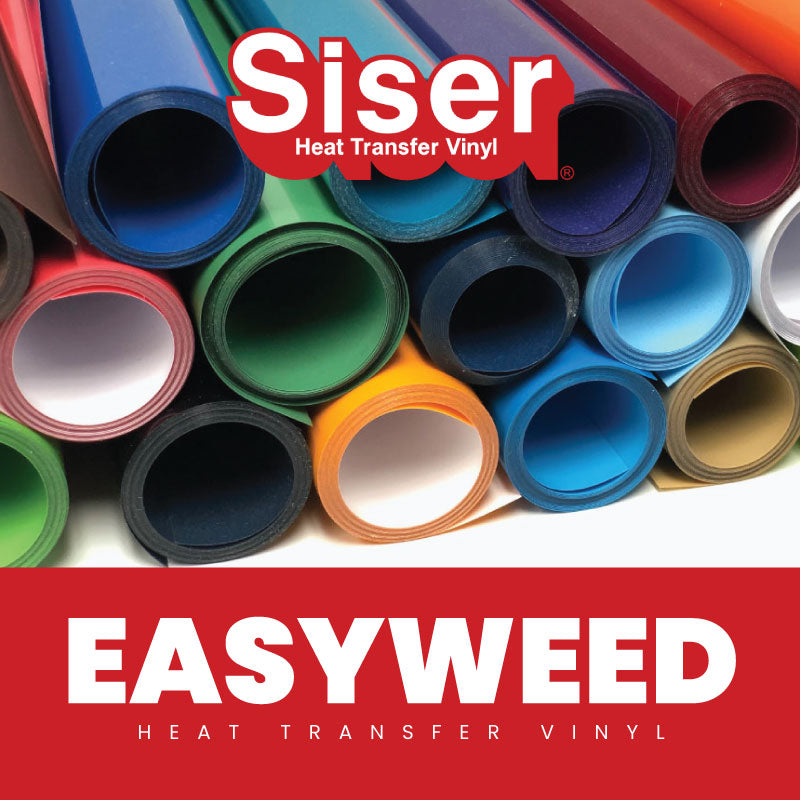

Occasionally, we receive inquiries from customers, some of whom are disappointed, about the discrepancy between the size of the sheets and rolls they receive and the size listed on our website. We recognize that vinyl and heat transfer vinyl may be unfamiliar to many crafters, so we would like to take this opportunity to clarify why the measurements are not always precise. A number of the items we offer are not exact in size, and this holds true regardless of where the product is purchased, as they are manufactured in this manner. For instance, Siser EasyWeed 15" rolls are actually 14.75" wide, and 12" Siser rolls are actually 11.8" wide. On the other hand, products like StarCraft HD are almost always exactly 24" wide, so when we cut them, they are true 12" wide rolls or true 12" x 12" sheets. We make every effort to specify the actual measurements on the product pages, but unfortunately, many individuals overlook these details.

Roll sizes are not exact becuase "master rolls" can vary among manufacturers. For instance, Siser's master rolls are 59" wide, which means they can be cut into either five rolls that are 11.8" wide or four rolls that are 14.75" wide. Despite being labeled as 20", Siser Glitter HTV rolls are actually 19.66" wide. These measurements remain consistent regardless of the retailer from which you purchase the product. For example, the 12" wide rolls of Siser HTV available at Michael's are actually 11.8" wide, as indicated on the label.

It is common practice in the industry to sell sheets and roll sizes without specifying the actual measurements on the product name. If we were to include the measurements while our competitors do not, we risk losing business and leaving customers dissatisfied. The majority of industry professionals are already familiar with the sizes, which is why complaints are rare.

For those seeking clarification on the measurements and dimensions, here are some illustrations:

12" x 15" Sheets Siser EasyWeed, Stretch, Electric, and others

These sheets are derived from a Siser 15" roll, which is actually 14.75" wide, resulting in sheets that are 12" x 14.75" in actual size.

12" x 12" Sheets Siser EasyWeed, Stretch, Electric, and others

These sheets are cut from a Siser 12" roll, which is actually 11.8" wide, making the sheets 11.8" x 12" in actual size.

12" x 24" Sheets Siser EasyWeed, Stretch, Electric, and others

These sheets are cut from a Siser 12" roll, which is actually 11.8" wide, resulting in sheets that are 11.8" x 24" in actual size.

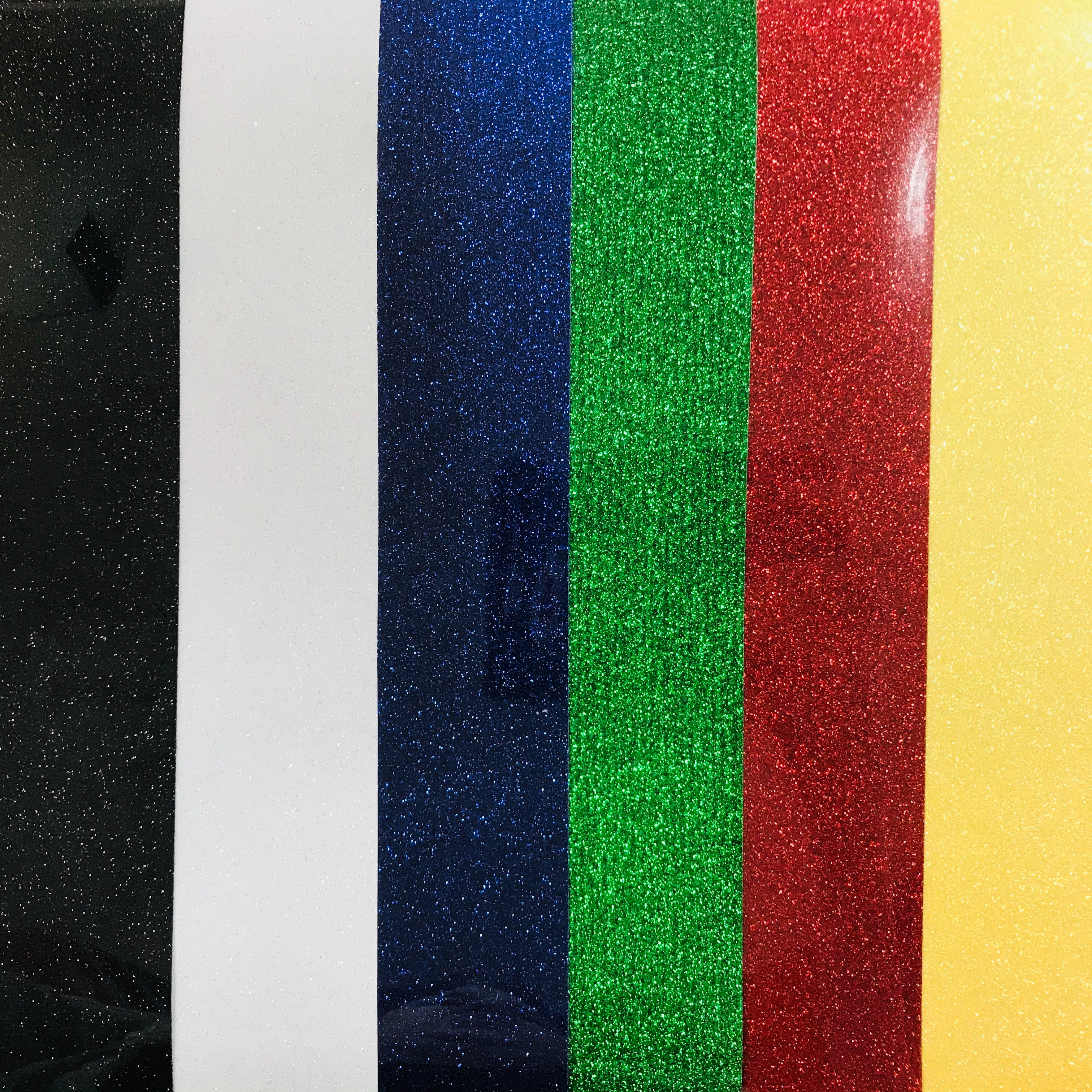

12" x 20" Sheets Siser Glitter and Holographic HTV

These sheets are cut from a Siser 20" roll, which is actually 19.66" wide, making the sheets 12" x 19.66" in actual size.

12" and 15" Wide Rolls of Siser HTV

As previously mentioned, the 12" wide rolls are actually 11.8" wide, and the 15" rolls are actually 14.75" wide, maintaining the specified width and length (5 feet, 5 yards, etc.).

12" and 24" sheets and rolls of adhesive vinyl

Most adhesive vinyl sheets and rolls are very close to the actual size, with a variance allowance of +/- 1/4" for cutting.