The custom apparel industry is constantly evolving, but few innovations have shaken things up quite like Direct-to-Film (DTF) printing. If you’ve been browsing forums or social media groups for apparel decorators, you’ve likely seen the buzz. People are calling it a "game-changer" and a "vinyl killer." But what exactly is it, and does it live up to the hype?

At Atlanta Vinyl, we believe in empowering our customers with the knowledge to make the best decisions for their businesses. In this guide, we’ll break down exactly how DTF printing works, walk you through the process step-by-step, and help you decide if this technology is the right move for your shop.

What is DTF Printing?

DTF stands for Direct-to-Film. As the name suggests, this process involves printing a design directly onto a special film, which is then transferred onto a garment using heat and pressure.

Unlike sublimation, which is limited to white polyester fabrics, or screen printing, which requires complex setups for each color, DTF is incredibly versatile. It works on cotton, polyester, blends, leather, nylon, and more—regardless of the fabric color. The result is a vibrant, durable, and soft-to-the-touch print that rivals traditional methods.

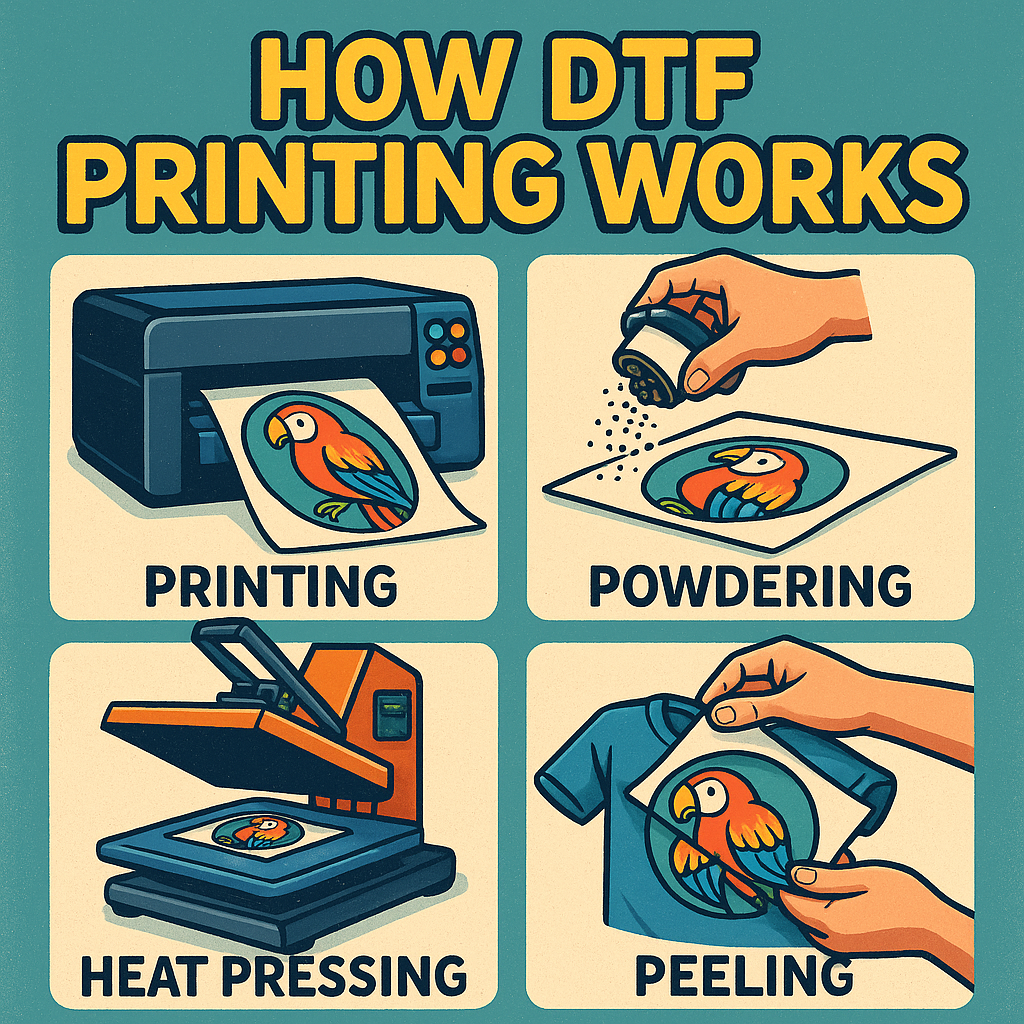

The DTF Process: Step-by-Step

Understanding the workflow is key to determining if DTF fits your production style. Here is how a DTF transfer goes from a digital file to a finished shirt.

Printing the Design

The process starts with a specialized inkjet printer equipped with textile inks. The printer prints the design onto a sheet or roll of PET film (the "film" in Direct-to-Film).

- CMYK Layer: First, the printer lays down the colors (Cyan, Magenta, Yellow, Black) to create the image.

- White Underbase: Immediately after the colors are printed, the printer lays down a layer of white ink directly on top of the wet colors. This white layer acts as the background for the design, ensuring the colors pop even on black or dark garments.

Powdering

While the ink is still wet, a special hot-melt adhesive powder is applied to the print. This powder sticks only to the wet ink and not the surrounding film.

- In manual setups, you might sprinkle this powder by hand.

- In automated commercial setups, a shaker machine applies the powder evenly and vibrates to remove any excess.

Curing

Once powdered, the film must be cured. The film is passed through a heating tunnel or placed under a heat press (without touching it) to melt the adhesive powder. This turns the powder into a smooth, rubber-like coating that bonds the ink to the film. Once cured, the transfer is stable and can be stored for later use or shipped to customers.

Pressing

This is the easy part! You place the transfer on your garment and press it using a commercial machine like a MEM Heat Press. The heat activates the adhesive, bonding the print to the fabric fibers.

Peeling

After pressing, the film is peeled away, leaving the design on the shirt. Depending on the film used, this might be a hot, warm, or cold peel.

Is DTF Printing Right for You?

Now that you know how it works, the big question is: Should you invest in it? Let's compare it to other popular methods like vinyl and sublimation to help you decide.

The Case for DTF

Versatility is King

Unlike sublimation prints, which require light-colored polyester, DTF works on almost anything. Cotton t-shirts, polyester jerseys, denim jackets, canvas bags—you name it. This flexibility allows you to say "yes" to more customer requests.

No Weeding

If you have ever spent hours weeding intricate designs from Oracal vinyl, you will appreciate this. DTF requires zero weeding. The printer does the work, handling fine lines, small text, and complex halftones that would be impossible with traditional vinyl cutting.

Durability and Feel

Early versions of heat transfers felt like a thick plastic patch. Modern DTF prints are soft, stretchable, and incredibly wash-fast. When applied correctly, they don't crack or peel easily.

Special Finishes

The technology is advancing rapidly. You can now get specialty films to create unique effects, such as Glitter DTF, which adds sparkle without the mess of loose glitter.

The Potential Drawbacks

Maintenance

DTF printers, especially the white ink channels, require regular maintenance. If you don't run the printer daily or keep up with cleaning, the print heads can clog, leading to expensive repairs.

Learning Curve

While pressing is easy, managing the printing environment (humidity and temperature) and color profiling can take time to master.

Initial Investment

A reliable commercial DTF setup (printer + shaker/dryer) is a significant investment compared to a hobby cutter.

Buy the Printer vs. Buy the Transfer

This is the most common dilemma for small shops.

You Should Buy a Printer If:

- You have a high volume of daily orders (50+ shirts a day).

- You need immediate turnaround times and can't wait for shipping.

- You have the budget for equipment and the discipline for daily maintenance.

You Should Buy Transfers If:

- You are a smaller shop or a hobbyist.

- You want to avoid the headache of printer maintenance.

- You want to offer professional quality without the overhead cost.

- You enjoy the simplicity of just pressing.

At ATL Vinyl, we bridge this gap. If you aren't ready to buy a printer, you can order high-quality custom DTF transfers directly from us. We handle the messy work of printing, powdering, and curing, so all you have to do is press and profit. We even offer custom sublimation transfer options if you prefer that method for polyester goods.

DTF printing has undeniably earned its place in the decorator's toolkit. It combines the full-color capability of digital printing with the versatility of heat transfers. Whether you choose to invest in your own machine or partner with a reliable transfer provider like Atlanta Vinyl, adding DTF to your offering is a surefire way to grow your business.

Ready to see the difference for yourself? Explore our collection of transfers, films, and presses today and take your apparel business to the next level.