Choosing your first or next heat press is a major step in growing your custom apparel business or hobby. Among the many types available, the clamshell style is one of the most popular due to its space-saving design and ease of use. But within this category, you’ll face a key decision: should you get a manual or an auto-open model? While both can produce professional-quality results, they operate differently and cater to different needs.

The right choice depends on your workflow, production volume, budget, and even your multitasking habits. Understanding the fundamental difference between a manual and an auto-open press will help you invest in a machine that not only fits your current projects but also supports your future growth. Let's compare these two powerful tools to see which one is the perfect fit for you.

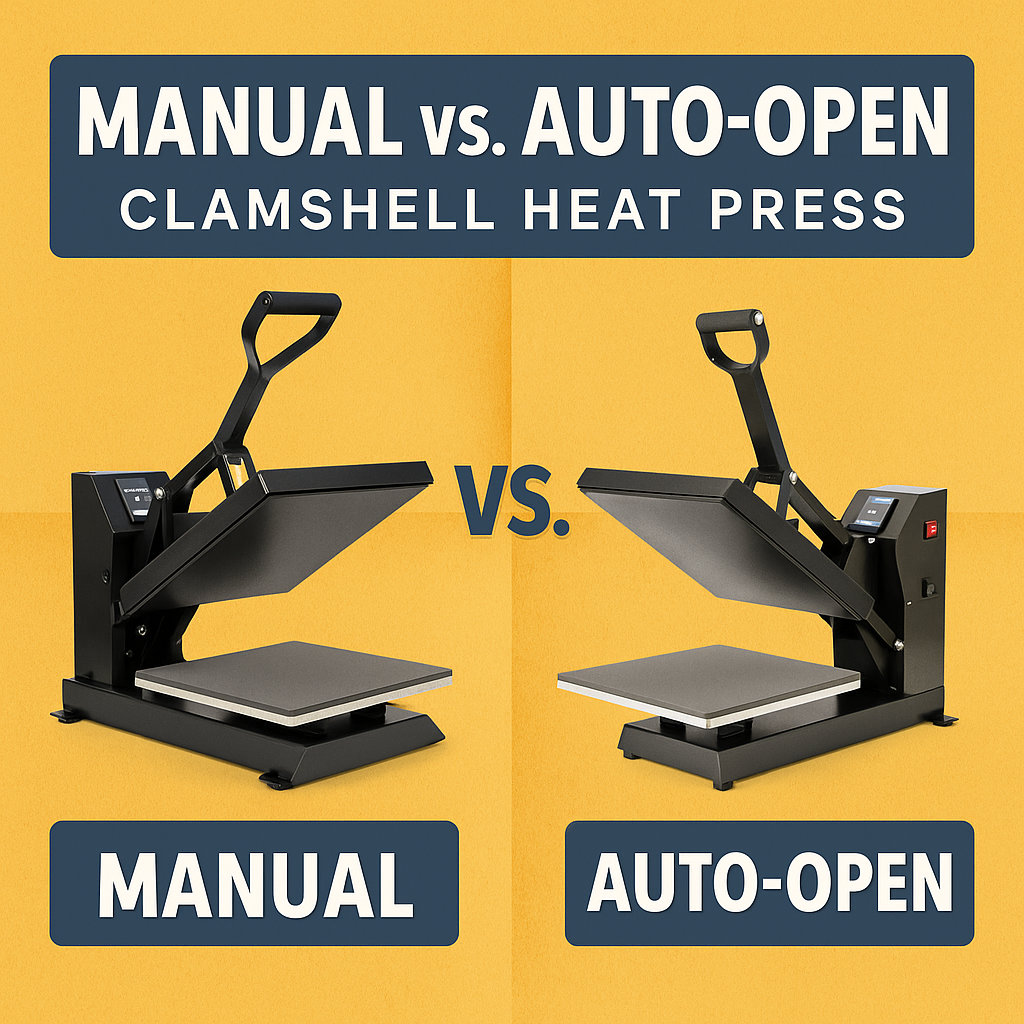

Understanding the Clamshell Heat Press

Before diving into the manual vs. auto-open debate, let's quickly review what a clamshell heat press is. As the name suggests, it opens and closes like a clamshell. The top platen is hinged at the back and lifts straight up, allowing you to place your garment and transfer on the stationary bottom platen. This design is compact, making it an excellent choice for crafters with limited space in a home office or small workshop.

The core function of both manual and auto-open models is the same: to apply specific heat and pressure for a set amount of time to adhere a transfer (like HTV, sublimation, or screen-printed transfers) to a substrate. The key difference lies in what happens when the timer goes off.

The Manual Clamshell Heat Press: The Hands-On Workhorse

A manual clamshell heat press is the most straightforward and often most affordable type of heat press. Its operation is entirely, as the name implies, manual.

How It Works

With a manual press, you are in control of every step. You close the press by pulling a handle down until it locks into place, applying the necessary pressure. You set the timer, and when it buzzes, you must be physically present to lift the handle and open the press. The machine will continue to apply heat and pressure until you intervene.

Advantages of a Manual Press

- Affordability: Manual presses are generally the most budget-friendly option, making them an excellent entry point for hobbyists or new businesses. Their simple mechanics mean lower manufacturing costs, which are passed on to the consumer.

- Simplicity and Reliability: With fewer moving parts and no complex electronics for the opening mechanism, there are fewer things that can break. These machines are known for their durability and long lifespan.

- Full Control: The operator has complete control over the pressing cycle. While this is a responsibility, some users prefer the hands-on approach and the tactile feedback of manually locking and unlocking the press.

Disadvantages of a Manual Press

- Risk of Over-Pressing: The biggest drawback is the potential for human error. If you get distracted by a phone call, a customer, or another task and don't open the press the second the timer goes off, you will over-press your garment. This can scorch the fabric, ruin the transfer, and create a "pressure box" mark on the shirt.

- Physical Effort: Operating a manual press requires a bit of physical strength to lock and unlock the handle, especially when using firm pressure settings. This can lead to fatigue during long production runs with many garments.

- Lower Productivity: Because you must be present to open the press, you cannot effectively multitask. Your attention is tied to the machine for the duration of each press, which can slow down your overall workflow.

Who Is a Manual Press For?

A manual clamshell press is perfect for:

- Beginners and Hobbyists: Those just starting with custom apparel who have a limited budget.

- Low-Volume Producers: Crafters who make items for friends, family, or a small Etsy shop.

- Users with a Dedicated Workspace: Individuals who can give their undivided attention to the pressing process without frequent interruptions.

The Auto-Open Clamshell Heat Press: The Smart Multitasker

An auto-open heat press, also known as a semi-automatic press, offers a significant upgrade in convenience and safety. It combines the control of a manual press with an automated release mechanism.

How It Works

You still close an auto-open press manually by pulling down the handle. However, it uses an electromagnet to hold the top platen down. When the timer you've set reaches zero, the electromagnet releases, and the press automatically pops open on its own.

Advantages of an Auto-Open Press

- Prevents Scorching and Over-Pressing: This is the single greatest benefit. The automatic release guarantees that your garment is only pressed for the exact time required. You can walk away to prepare the next shirt, weed another design, or answer an email without worrying about ruining your project.

- Increased Productivity: The "set it and forget it" nature of an auto-open press is a game-changer for workflow efficiency. It frees you up to multitask, effectively allowing you to run a mini-assembly line. While one shirt is pressing, you can be getting the next one ready, significantly increasing your output.

- Ease of Use and Reduced Fatigue: While you still close it manually, the auto-open feature eliminates the need to be standing by to lift the handle. This reduces physical strain and mental load, making long production sessions more manageable.

Disadvantages of an Auto-Open Press

- Higher Cost: The added technology of the electromagnetic release mechanism makes auto-open presses more expensive than their manual counterparts. This initial investment can be a barrier for some new users.

- More Complex Mechanics: While generally very reliable, the added electronics and magnetic components introduce more potential points of failure over the long term compared to a simple manual machine.

Who Is an Auto-Open Press For?

An auto-open clamshell press is ideal for:

- Growing Businesses: Anyone looking to increase their production volume and efficiency.

- Multitaskers: Business owners or crafters who need to manage multiple tasks simultaneously in their workspace.

- High-Volume Producers: Those who press dozens or hundreds of shirts in a session will see a massive return on investment in time and energy saved.

- Users Concerned with Quality Control: The precision timing ensures every garment is pressed perfectly, leading to consistent, professional results.

Making Your Choice: Key Questions to Ask

To decide which press is right for you, consider these questions:

- What is my budget? If you have a strict, lower-end budget, a manual press is a great way to start without compromising on core functionality. If you can afford the higher initial cost, an auto-open press is often worth the investment.

- How many items will I be making? For occasional one-off projects, a manual press is sufficient. If you plan to fulfill orders regularly or produce in batches, the efficiency gains from an auto-open press are invaluable.

- How will I be working? Are you easily distracted? Do you need to perform other tasks while the press is running? If so, the safety net provided by an auto-open feature is a must-have.

- What are my long-term goals? If you plan to grow your hobby into a business, investing in an auto-open press from the start can save you from needing to upgrade later. It's a tool that can grow with you.

Your Press, Your Workflow

Both manual and auto-open clamshell heat presses are fantastic tools that can create beautiful, sellable products. A manual press offers affordability and simple reliability, making it a perfect starting point. An auto-open press, on the other hand, is an investment in efficiency, consistency, and peace of mind. By evaluating your production needs and work habits, you can confidently choose the machine that will become the cornerstone of your creative endeavors.

Ready to find the perfect heat press to bring your designs to life? Explore our range of machines to find the model that best suits your goals.