Sublimation printing allows you to create stunning, full-color designs that become a permanent part of your apparel or promotional items. While we often focus on the ink and the heat press, there is a quiet, unsung hero that makes the entire process possible: sublimation paper. This isn't just any paper; it's a specialty product engineered to perform a very specific and crucial task.

This guide will pull back the curtain on sublimation paper. We'll explore what it is, how it works its magic during the heat transfer process, and why investing in high-quality paper is essential for achieving the vibrant, professional results you want. Understanding the role of this critical component will elevate your sublimation game from good to great.

What is Sublimation Paper?

At first glance, sublimation paper might look like ordinary printer paper, but it is a highly specialized material. It is a base paper coated with a unique layer of microporous material, typically silica and a binder. This coating is designed with one primary goal: to hold onto sublimation ink during printing but release as much of it as possible when heated.

Think of it as a temporary carrier for your design. Its job is to absorb the liquid sublimation ink from your printer, hold the ink droplets in place with minimal spreading, and then let go of that ink as a gas when it's subjected to the high heat and pressure of your press. This controlled release is the key to a sharp, vibrant, and efficient transfer.

The Role of Sublimation Paper in the Transfer Process

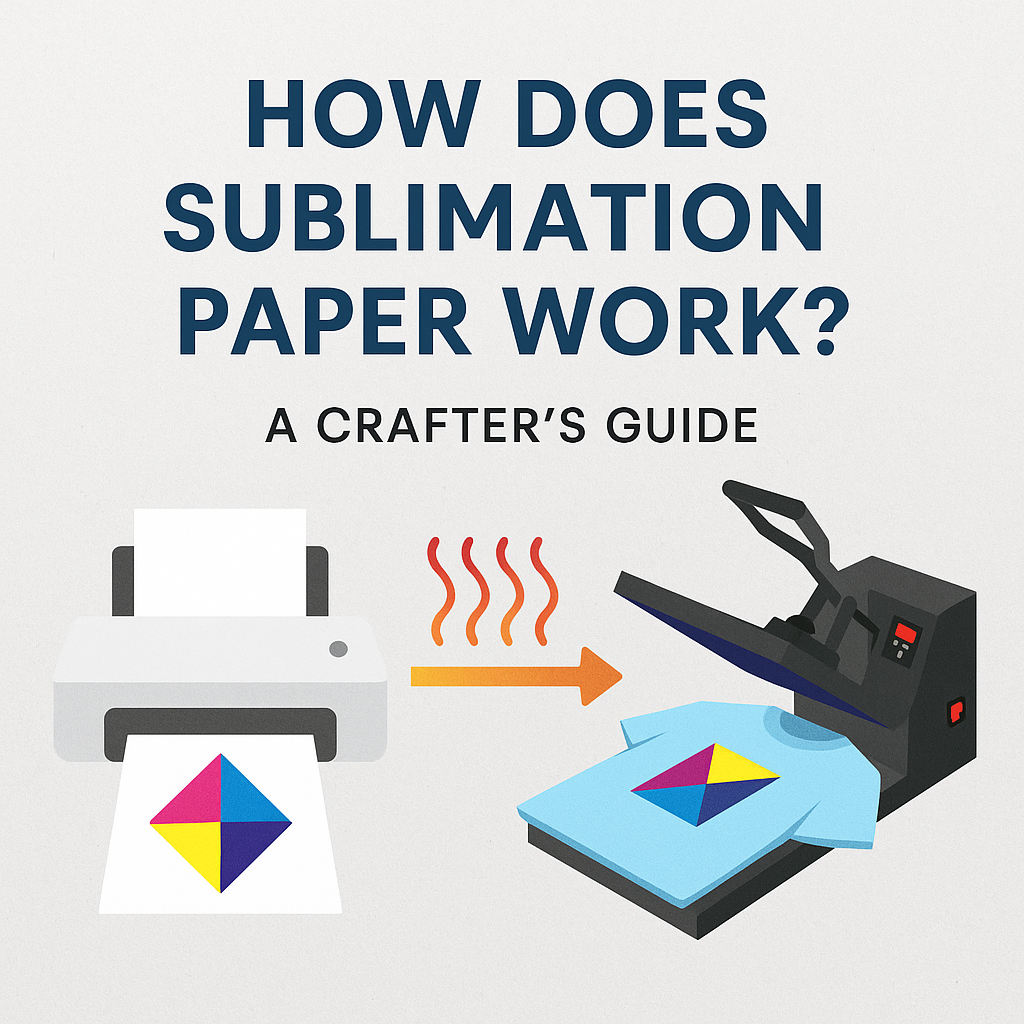

The magic of sublimation paper becomes clear when you look at its role step-by-step in the printing process.

Step 1: Printing - Capturing the Ink

When you send your design to your sublimation printer, it sprays microscopic droplets of sublimation ink onto the paper. The special coating on high-quality sublimation paper is engineered to keep these droplets from soaking deep into the paper fibers. Instead, the ink sits right on the surface within the microporous layer.

This has two main benefits:

- Prevents Bleeding: It keeps the ink droplets tight and distinct, which prevents them from spreading and blurring. This is essential for creating crisp lines and sharp details in your final design.

- Maximizes Ink Availability: By keeping the ink on the surface, the paper ensures that the maximum amount of ink is ready to be turned into gas during the next step.

Step 2: Heating - Releasing the Ink as Gas

This is where the paper truly performs. When you place the printed paper onto your sublimation blank (like a polyester shirt or a coated mug) and apply heat and pressure, two things happen simultaneously.

First, the solid sublimation ink on the paper turns directly into a gas, skipping the liquid phase entirely. Second, the heat causes the special coating on the paper to open up its pores, releasing this gas. This gaseous ink then travels from the paper to the sublimation blank.

Step 3: Bonding - Creating a Permanent Design

At the same time, the heat has also opened the pores of the polyester fibers in your garment or the polymer coating on your hard good. The gaseous ink finds these open pores and embeds itself deep within them. As soon as you remove the heat and the item begins to cool, the pores close, permanently trapping the ink inside the material.

The design is now part of the substrate itself. It's not sitting on top like a sticker or a layer of vinyl. This is why sublimated designs have no feel, or "hand," and why they are incredibly durable, with no risk of cracking, peeling, or fading.

Why High-Quality Paper is a Non-Negotiable

You might be tempted to save money by using cheaper paper, but this is one area where quality directly impacts your final product. Using low-quality paper can lead to a host of problems.

Poor Ink Release

The most common issue with cheap paper is a low ink-release rate. If the paper's coating isn't formulated correctly, it won't let go of all the ink when heated. This means less ink gets transferred to your blank, resulting in a dull, faded, and washed-out design. A high-release paper, like those offered at Atlanta Vinyl, ensures that over 95% of the ink is transferred, giving you the brightest and most saturated colors possible.

Ink Bleeding and Blurring

Low-quality paper often lacks a proper coating to control ink spread. The ink soaks into the paper fibers and bleeds, causing fuzzy edges and a blurry final image. If you want sharp, photographic-quality results, you need a paper that can hold the ink droplets precisely where they are printed.

Inconsistent Results

Cheaper papers can have inconsistent coating thickness across the sheet. This can lead to blotchy or uneven transfers, where some parts of the design are vibrant and others are faded. Professional-grade paper is manufactured to strict standards to ensure a uniform coating for reliable and repeatable results every time.

Paper Curling and Jamming

Sublimation paper is subjected to the high heat of a printer's fuser unit and a heat press. Poorly made paper is prone to curling from the heat and moisture, which can cause printer jams or make it difficult to lay the transfer flat on your blank, potentially leading to ghosting or double images.

Tips for Choosing and Using Sublimation Paper

- Know Your Printer: Most sublimation paper comes in various sizes (sheets and rolls) to fit different printers. Ensure you buy the size that is compatible with your equipment.

- Identify the Printing Side: Sublimation paper has a printing side (the coated side) and a non-printing side. The printing side is typically bright white and smoother. Many brands print a watermark or logo on the back to make it easy to identify. Printing on the wrong side will result in a failed transfer.

- Store It Properly: Keep your sublimation paper in a cool, dry place, preferably in its original packaging or a sealed container. Moisture is the enemy of sublimation paper and can cause issues with printing and transferring.

- Don't Skimp on Quality: Your final product is only as good as the weakest link in your process. Investing in high-quality sublimation paper is one of the easiest ways to ensure consistently vibrant and professional results.

Sublimation paper is far more than just a piece of paper; it's a sophisticated tool that plays a pivotal role in the quality of your finished products. It masterfully holds and then releases your design, acting as the perfect bridge between your digital creation and your physical product. By understanding how it works and choosing a high-quality paper, you empower yourself to create the brilliant, permanent, and impressive sublimation projects you’ve always imagined.